Process and applications of UV printing2024-09-03

Digital printing is one of the most rapidly evolving technologies today, revolutionizing printing processes across various fields. UV printing is a specialized branch of this modern printing technology, which has gained significant popularity in recent years. In 2023, we performed 17% more UV printing compared to the previous year, while the number of pad-printed products decreased by the same margin. But what exactly is UV printing, what are its advantages, and why is it becoming an increasingly widespread technology?

The essence of digital printing is that the process starts directly from a digital format, eliminating the need for printing plates, as required by traditional printing methods. This results in significant time and cost savings, as digital files can be easily and quickly modified. UV printing uses ultraviolet light technology to instantly cure the inks, providing unique quality and durability. As the printer distributes the ink across the material's surface, ultraviolet light follows closely, instantly drying or curing the ink.

UV Printing is versatile and applicable on many materials.

Traditional vs. Digital UV Printing

Traditional printing techniques such as offset printing, screen printing, and pad printing have long dominated the printing on promotional gifts' industry. These methods are precise and excellent for large-volume printing tasks. However, their drawbacks include time-consuming and expensive processes, especially for small print runs.

Traditional printing methods use inks with special solvents that evaporate into the air. The evaporation of these solvents helps the ink absorb into the material, and as the solvents evaporate, the ink dries. To facilitate drying, additional powders may also be needed during the process.

In contrast, digital printing, particularly UV printing, offers a faster and more flexible solution. In UV printing, UV light follows the print, instantly solidifying the ink, making the process not only faster but also cleaner and more environmentally friendly. The process is quick, and the digital image is ready within seconds. Since the solvents evaporate only minimally and the ink hardly absorbs into the surface, UV inks can be printed on virtually any material.

Advantages of UV Printing

UV printing offers several advantages that set it apart from traditional printing techniques:

- Environmentally Friendly: UV printing uses fewer solvents and chemicals, reducing environmental impact. Since UV inks dry instantly and do not emit VOCs (Volatile Organic Compounds) into the environment. UV printing is considered a green technology, safe for the environment, and leaves a negligible carbon footprint. This process has been a breakthrough, particularly in the food industry. Traditional printing methods were harmful due to the high risk of food contamination when ink materials came into contact with food in packaging. These inks never fully dried, and the risk of contamination was always present.

- High Quality: The technology produces photo-quality prints that are extremely sharp and detailed.

- Color Fastness, Vivid Colors: UV printing provides a more vibrant finish since the UV light doesn't allow the ink to absorb into the paper/material. This technique achieves photorealistic printing. UV prints do not fade and retain their lively colors over time.

- Broader Range of Printing Applications: UV printing can be applied to almost any surface, including paper, fabric, textiles, plastics, and metals. The LED drying process emits minimal heat, making it possible to print on heat-sensitive substrates like adhesive sheets, thin films, or items with meltable interiors.

- Speed: UV printing is much faster than traditional printing. There is no need to wait for the ink to dry, as polymerization occurs almost instantly under ultraviolet light.

- Cost-Effective: Significant cost savings can be achieved as the fast-drying process allows for greater efficiency (producing more units in a given time), and there is no need for plates or screens.

- Small Quantity Printing: Ideal for producing samples and low-quantity prints, as there is no lengthy preparation process involved.

Disadvantages of UV Printing

- Color: Due to CMYK printing, UV printing does not provide Pantone color accuracy.

- Surface: Primarily applicable to flat surfaces where there are no protruding parts on the product

What Kind of Products can UV Printing be used on?

UV printing has proven its versatility and efficiency across many industries and applications. Here are some examples of common application areas:

Textile Printing: Printing on fabrics, clothing (t-shirts, sweaters, jackets, vests), and other textiles where durability and color fastness are essential requirements.

Promotional Items: Printing on keychains, water bottles, notebooks, toys, drawing tools, kitchen utensils, and other personalized promotional items.

Advertising Materials: Printing on posters and billboards where color and detail preservation are crucial.

Industrial Applications: Printing on plastics and metal surfaces, such as marking technical equipment and components.

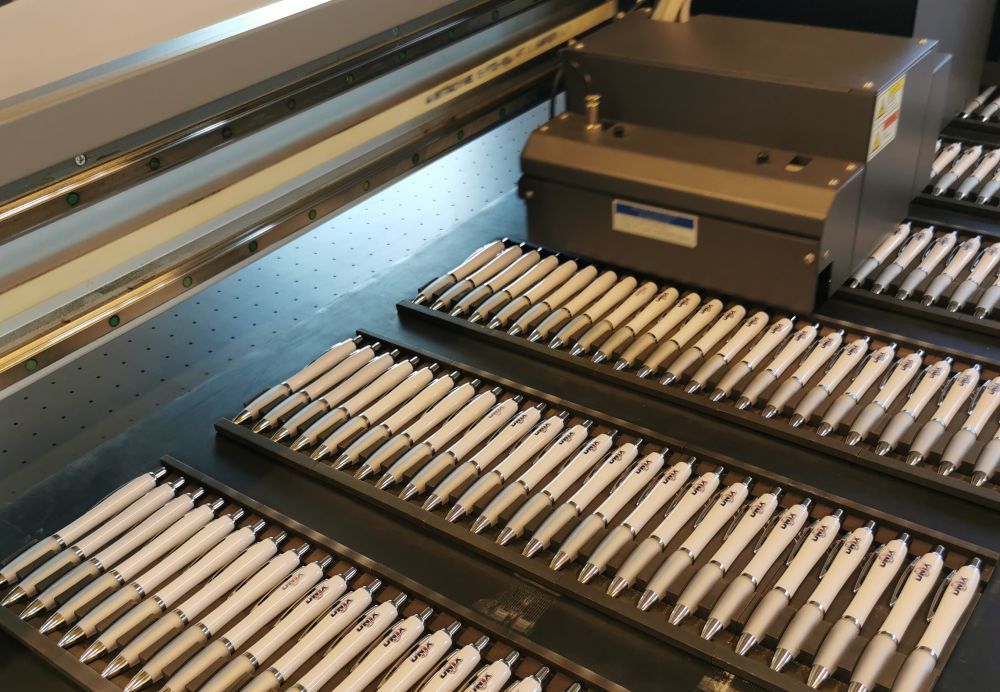

The above image created by AI contrasts with what an actual UV printing machine looks like. :)

Summary

UV printing is an industry trend. In the coming years, it will continue to expand and find applications in more industries. Due to its cost-effectiveness, environmental friendliness, and versatility, UV printing is undoubtedly the future of the packaging and printing industry.

Thus, UV printing is not just another printing technology but a revolutionary solution that opens up new opportunities for many industries. Time savings, versatility, eco-friendliness, as well as excellent quality and color durability, all contribute to the growing prominence of UV printing in the modern printing industry.

Get in touch with us, and with over 30 years of experience, we will handle the task from product design to packaging and delivery. Thanks to our significant inventory, you are sure to find what you need with us, whether it's a pad-printed water bottle, mechanical pencil, notebook, folder, kitchen utensil, or any other promotional gift for promoting your business. In our facility, we print, engrave, stitch, iron, and more on anything and everything.

You can also read a summary guide on other available branding techniques.

Image sources: ChatGPT 4.0 and our own photos.

1010 Meinungen nach

Familienunternehmen

Produktsortiment

seit 2003

Bürogebäude

Verlangen Sie nach unserem Newsletter, damit Sie keines unserer Sonderangebote verpassen!